Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

March 4, 2025

I have shared the ASME and NBIC “code” requirements for these arrangements and it has already stirred a number of debates/questions; of which the API has offered some excellent guidance on this design.

(emphasis by me)

…

HomeRead More »

Read More

March 3, 2025

It has grown tiresome, but it remains a teachable moment, to debate “engineers” who want part of ASME/NBIC to be the gospel and other parts not so much. The ammonia refrigeration industry just can’t seem to grasp the critical need in their “Common PRV Header Design” v.s. having more “holes in the roof” (as they like to point out). And today, I got word a technician...

Read More

March 2, 2025

Recently I was asked if “torquing” threaded pipe is required by code. I answered the inquiry by referring the client to ASME B1.20.1-2013, which states: 1.4 Sealing (NPT and NPSC Only)…1.4.3 Tightening Torque.Due to application-specific variables such as materials, wall thickness, operating pressures, etc., no guidance is given in this Standard regarding joint-tightening torque. However,...

Read More

March 2, 2025

Another incident where the lack of respect for static electricity and flammable atmospheres results in severe injuries. A Teflon bristle brush generates a lot of static electricity; coupled with the low flashpoint of Naptha (73F) and we have a serious hazard. At 5:30 a.m. on February 24, 2020, an employee, 42, was scrubbing interior surfaces of a mix tank with 1-2 gallons of petroleum naphtha using...

Read More

March 2, 2025

FACT: Most flammable liquid vapors have a Minimum Ignition Energy (MIE) of less than 1 millijoule (mJ). Most of us do not even feel static which is less than 15 mJ. So the amount of energy necessary to ignite most flammable vapor atmospheres is not even observable by humans. At 6:15 p.m. on October 30, 2020, an employee, 38, working for a natural gas distributor was using a hand hose to transfer diesel...

Read More

March 2, 2025

At 2:45 p.m. on May 31, 2024, Employee #1, 39, was performing welding work on a diesel fuel tank. During the welding process, an explosion occurred, resulting in the employee’s fatal injuries. The explosion was caused by overpressure inside the tank, which caused metal parts to be ejected. Emergency services responded to the scene, but the employee was pronounced dead from injuries sustained...

Read More

March 2, 2025

There’s a massive difference that may require massively different approaches in how we respond to failures in administrative controls such as LOTO. Scenario #1: a worker with less than a year of experience, is tasked with isolating a PRCS that has 29 isolation points. It was his first time to do this isolation and was asked to “step up” by his supervisor since they were “short-handed” and dealing with...

Read More

March 2, 2025

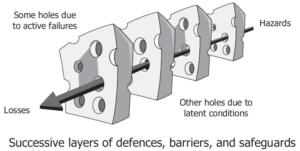

In memory of James Reason, I thought it would be fitting to share, in my professional opinion, one of the greatest safety models of my career. If businesses could just embrace this model when it comes to how they investigate events, we could move workplace safety forward a couple of decades. The model is quite simple and has proven to make sense of people’s errors, mistakes, and violations. I...

Read More

March 2, 2025

Back in June of 2021, a 1.5 million gallon water tank exploded just as a contractor began to perform hot work on it. Now most people would think a water tank would not have explosive properties; thus, the workers, nor the deceased contractor with 16 years experience, did not sample the atmosphere within the tank. The explosion sent the massive tank 70′ into the air. But Methane gas can be entrained...

Read More

March 2, 2025

A lot of folks may not know that Hydrogen gas is used as a refrigerant on generators at power plants. When I first started working on power plants in 2005, I was shocked at this practice and at how some plants managed these risks. I have never done work for the company involved in this fatal H2 explosion, but their set up was very similar to others. LEARNING from the mistakes of others is key to accident...

Read More

March 1, 2025

By: Victor Dearman Jr. CIRO, CRST

Flagging tape is not LOTO! And never has been. I would bet good money the operating procedure for this compressor has LOTO covered, but those are just documents to look good in a binder sitting on a shelf collecting dust because they are viewed as a necessary evil to satisfy perceived compliance, “but that’s how we actually do it.”

It’s 2025. Do better!

Read More