April Membership Special

3-years for $100

Just buy a Single User Membership and your $100 gets you three (3) years of access instead of one (1) year

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

November 30, 2015

The National Board of Boiler and Pressure Vessel Inspectors has released its Third Quarter Report of Violation Findings for 2015. The data captures problem areas and trends related to boiler and pressure vessel operation, installation, maintenance, and repair; and also identifies problems before unsafe conditions occur. This report serves as an important source of documentation for jurisdictional...

Read More

November 29, 2015

This is a study done by Commission of the European Communities which looked at the causes and consequences of Ammonia Accidents in the-the EU. It is a nice breakdown of the accidents and their contributing factors that we may be able to learn from. Due to its massive use, ammonia is often involved in accidents. Ammonia is one of the single substance that has been rather often involved...

Read More

November 29, 2015

Liquid ammonia leakage accidents can cause serious consequences. This paper makes research on the liquid ammonia leakage accidents based on safety system engineering theory model. Shanghai Baoshan”8.31” liquid ammonia leakage accident is used as an example in this paper and the direct and indirect reasons for the accident are analyzed and combined into four factors: human, material...

Read More

November 29, 2015

This explosion is VERY SIMILAR to the fatal hotwork explosion that occurred in 2001 at Motiva Enterprises. The Motiva explosion occurred when a work crew had been repairing a catwalk above a sulfuric acid storage tank farm when a spark from their hot work ignited flammable vapors in one of the tanks. This tank had holes in its roof and shell due to corrosion. The tank collapsed, and...

Read More

November 29, 2015

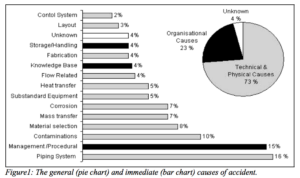

A study of past accidents in the chemical process industry (CPI) has been carried out by Helsinki University of Technology, Plant Design, Department of Biotechnology and Chemical Technology. It is found that the majority (73%) of the accidents were caused by technical and engineering failures. Based on the causes of accident and types of equipment failures, five common features of an accident...

Read More

November 29, 2015

After maintenance, a scaffold was taken away to be able to start the cooling fan. Seconds after start up of a cooling fan, there was a lot of noise and a metal scaffold deck flew through the air and fell on the ground. CLICK HERE (pdf) for the Incident Alert.

Read More

November 28, 2015

Anyone else notice the number of shocker photos making their rounds that show workers wearing their fluorescent safety vest while doing some awfully UNSAFE acts?!?!? I mean I get the idea with the hi-vis vests and all and I am a supporter of the concept, but I think some companies may be fooling themselves into thinking that issuing hi-vis vests eliminate unsafe acts. This pic shows...

Read More

November 28, 2015

And we wonder how accidents happen. From my observation, this does NOT appear to be a surprise to the workers! Seems they are fully expecting this to happen and right next to a roadway none the less.

Read More

November 27, 2015

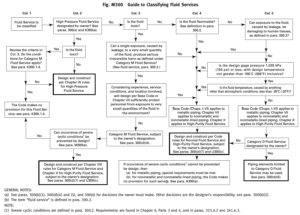

Back in 2012, I wrote an article about ASME’s “Lethal Service” definition in the hopes of providing some direction in how we could establish which of our HHC/EHSs may rise to the level of “lethal service” as it applies to the design of our pressure vessels. The article stirred much debate among the SAFTENG die-hards, but it also led to more questions. The most asked question...

Read More

November 27, 2015

A few months ago we discussed the first step in establishing our Dry Chlorine piping “service class” and in that article, I stressed how critically important that step was, as the rest of our design will be based on the chosen “service class”. In this article, we will see that I was not joking! As a reminder, here are our service classes: Service Class Physical...

Read More

November 27, 2015

No it is not a spongy football for kids! NURF is the acronym for “Normally Unoccupied and Remote Facility”. It is a term used in OSHA’s PSM standard and NURFs are EXEMPTED from complying with OSHA’s PSM standard; however, EPA’s RMP rule does NOT have a NURF exemption so be careful – EPA manages this type of exemption via their varying RMP Program Levels. With all...

Read More