Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

June 24, 2024

I was recently involved in a safety review at a client with two (2) separate LOTO failure events in a month. I know this client and the PM very well, and I was never more disappointed in their decisions about the discipline around these two (2) very different LOTO events. One event resulted in NO injury, and that employee received no discipline; the other event injured two workers (both...

Read More

June 23, 2024

Based on the feedback from other SAFTENG members, I have made this article public for the next 30 days. Much like the process safety debates around valve/equipment labeling, no RAGAGEP specifically requires a unique identifier on every valve or piece of equipment. Yet, labeling valves/equipment within the covered process is necessary to manage the process’s safety. Another debate we have...

Read More

June 23, 2024

Scenario: In your letter, you state that an employee who does not have a fixed work site left his home and traveled approximately 300 miles to a customer site. After the employee arrived at the customer site, he checked into a hotel and conducted work activities for several days. Once the work activities at the customer site were completed, the employee traveled to a relative’s home and stayed...

Read More

June 22, 2024

Recently, a client had two (2) heat-related incidents within one (1) week. This after, we forced a download of the OSHA/NIOSH Heat App to all company phones. I have used this technique to ensure front-line supervisors and managers have a TOOL to help them manage the Heat Prevention Plan requirements. I have used this forced download several times, and the results vary wildly. ...

Read More

June 22, 2024

EPA has found that major chemical accidents continue to occur from facilities that are not adequately managing the risks they pose to ensure the safety of their facilities and protect surrounding communities. Many of these communities have environmental justice concerns or face climate change-related hazards or both. Thousands of facilities nationwide make, use, and store extremely hazardous substances....

Read More

June 22, 2024

The Program 3 prevention program requirements under 40 CFR Part 68 are almost identical to the requirements of OSHA’s process safety management (PSM) standard. OSHA exempts certain industries from the PSM standard. Why does EPA not exempt those same industries from the CAA §112(r) risk management program requirements?

…

HomeRead More »

Read More

June 22, 2024

When selecting the worst-case release scenario for Program 2 and 3 processes as required by 40 CFR §68.25, a stationary source owner or operator must analyze the release scenario that results in the greatest distance to an endpoint. Does the “greatest distance to an endpoint” refer to the greatest total distance from the process (e.g., vessel or pipeline), or to the distance beyond the...

Read More

June 22, 2024

The alleged violations below have been grouped because they involve similar or related hazards that may increase the potential for injury or illness.

…

HomeRead More »

Read More

June 18, 2024

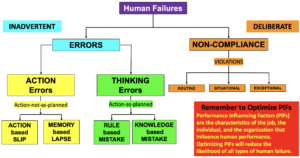

For me, SIF is just using Process Safety Management (PSM) tools for lower-frequency, higher-severity events, whereas traditional “recordable injuries” can be managed with the traditional Safety Management System (SMS). But here is the catch… the consequence may be more severe (serious), but the failures that led to those consequences can all be traced back to the failure of our Controls/Barriers/Safeguards...

Read More

June 17, 2024

Heinrich did not blame workers for accidents—quite the opposite. He was more in the camp of Latent Organizational Failures, as James Reason taught us in the 1980s. In this passage from his 1928 article “The Origin of Accidents”, Travelers, we can see his position on accidents on full display…

Remember, he said this 96 years ago!!!

…

HomeRead More »

Read More

June 9, 2024

In April 2023, EPA published a report on the first survey conducted of the State Emergency Response Commissions. The purpose of the survey was to learn how the Emergency Planning and Community Right-to-Know Act is currently implemented at the state and local levels, as required by the 1986 legislation, as well as its amendments of certain provisions in 2018. State Emergency Response Commissions are...

Read More

June 7, 2024

On Dec. 3, 2004, a 50,000-pound steel pressure vessel violently exploded at the southwest Houston Marcus Oil and Chemical facility. The pressure vessel contained flammable hydrocarbons such as hexane. The pressure vessel was a horizontal tank 12 feet in diameter, 50 feet long, and operated at a pressure of approximately 67 psi. Marcus Oil did NOT use a qualified welder or proper welding procedure to...

Read More