Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

May 14, 2024

May 2, 2024 MEMORANDUM FOR: REGIONAL ADMINISTRATORS STATE DESIGNEES THROUGH: AMANDA EDENS Deputy Assistant Secretary of Labor for Occupational Safety and Health FROM: SCOTT KETCHAM Acting Director, Directorate of Enforcement Programs LEE ANNE JILLINGS Director, Directorate of Technical Support and Emergency Management SUBJECT: Enforcement Guidance Under OSHA’s Recordkeeping Regulation When First...

Read More

May 13, 2024

The National Institute for Occupational Safety and Health (NIOSH) has honored a request by Honeywell International Inc. to voluntarily rescind two NIOSH respirator approvals issued to Honeywell International Inc. Due to the voluntary rescission of these NIOSH approvals, respirators bearing these NIOSH approval numbers MAY NO LONGER BE USED, manufactured, assembled, sold, or distributed. As of...

Read More

May 13, 2024

The Department of Health and Human Services (HHS) proposes to amend regulatory requirements that would be used by the Centers for Disease Control and Prevention’s (CDC) National Institute for Occupational Safety and Health (NIOSH) to test and approve Combination Unit Respirators (CURs). NFPA defines a CUR as…

…

HomeRead More »

Read More

May 13, 2024

MultiVapor™ has been updated to resolve the errors users experienced with a missing MSSTDFMT.DLL file, and other minor typographical errors. MultiVapor™ is a computer tool for estimating breakthrough times and service life of air-purifying respirator cartridges manufactured to remove toxic organic vapors (OV) from breathed air. It can also be used for larger filters and for carbon beds of any size...

Read More

May 12, 2024

On May 2, 2023, an employee working for a gas station and convenience store arrived to talk to a coworker (the employer) about payment for the building he leases. The employee asked the coworker if he could help him apply a fuel tank liner.

The employee climbed inside the tank and plugged in his own light into an extension cord.

…

HomeRead More »

Read More

May 12, 2024

Respondents owned and operated a seafood processing and cold storage warehouse facility. The Facility is one building that consists of two separate spaces on either side of a dividing wall. One side of the Facility is used for seafood processing and packaging. The other side of the Facility is a cold storage warehouse used to store the packaged seafood. The Facility is located alongside Gloucester’s...

Read More

May 11, 2024

If you want a spirited process safety debate, simply mention the practice of having “intervening valve(s)” before or after a Pressure-Relieving Device (PRD). There are some who swear that it is not allowed, but in fact, it is. This is how I learned about the “Car-Seal” program early in my career. ASME B31.12 is one of those RAGAGEPs that allows this practice...

Read More

May 10, 2024

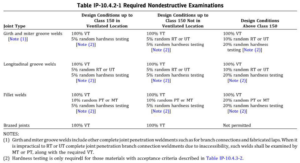

I have written many articles relating to ASME B31.3 and the QA/QC requirements each weld/flange must meet. However, in B31.12, Table IP-10.4.2-1 Required Nondestructive Examinations, the code requires 100% VT (Visual examination). The code goes on to require a more extensive examination sampling of 5-10% joints using with Liquid Penetrant (PT) or Magnetic Particle (MT). Even the VT...

Read More

May 10, 2024

Valves that must be operated during an emergency shall be

examined periodically and

partially operated at least once a year

to provide safe and proper operating conditions. Routine valve maintenance procedures shall include, but not be limited to, the following:

…

HomeRead More »

Read More

May 10, 2024

Each operating company shall establish written procedures to minimize the hazard of an emergency. The procedures shall provide instructions to operating and maintenance personnel. The procedures shall describe the following: a process for prompt and adequate handling of all calls that concern emergencies, whether they are from customers, the public, employees, or other sources, and for classifying...

Read More

May 10, 2024

As I dig deeper into ASME B31.12, Hydrogen Piping, I continue to find nuggets of best practices for HAZMAT piping. ASME B31.12 requires each operating company having industrial piping, pipeline, and commercial and residential systems to have Operational, Maintenance, and Emergency Plan(s) that include the following:

…

HomeRead More »

Read More

May 9, 2024

On April 24, 2024, the department’s Occupational Safety and Health Administration presented the draft rule’s initial regulatory framework at a meeting of the Advisory Committee on Construction Safety and Health. The committee, which advises the agency on safety and health standards and policy matters, unanimously recommended OSHA move forward expeditiously on the Notice of Proposed Rulemaking....

Read More