CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

We offer:

- Over 17,600 categorized unsafe acts/conditions and accident/injury photos

- Over 1,450 ppt's & doc's

- Over 3,975 technical articles on Process Safety & Occupational Safety & Health matters

- Over 450 videos

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

January 3, 2012

We Believe

…That every man or women bears the unalterable responsibility for keeping out of harm’s way. This he or she owes to him or herself, their family, their fellows and his or her job.

…

HomeRead More »

Read More

January 2, 2012

Oily waste safety cans are an essential safety device where ever cloths and wiping rags are used with oils and solvents. Rags and cloths soaked with solvents, thinners, linseed oil, combustible adhesives and other flammable liquids present a serious fire risk if they are improperly discarded. These safety cans are specially designed to isolate it’s contents from fire sources and limiting...

Read More

December 31, 2011

Most businesses have established their safe upper and lower limits for the most obvious process parameters such as pressures, temperatures, and levels; but in a flammable liquid process involving non-conductive flammable liquids establishing a safe upper and lower limit for flow is an ABSOLUTE MUST. There is not a Recognized and Generally Accepted Good Engineering Practice (RAGAGEP) on flammable...

Read More

December 31, 2011

In the last two years we have seen a dramatic increase in the use of Anti-Static Wrist Bands in industrial settings. These wrist bands are designed and manufactured for “bench work” in highly controlled work spaces; not within an industrial setting.

…

HomeRead More »

Read More

December 30, 2011

Published by the Occupational Safety and Health Service, Department of Labour – Wellington, New Zealand

First published: 1982; Revised: 1990

…

HomeRead More »

Read More

December 30, 2011

Precautions should be taken to prevent vapors from being ignited by the discharge of static electricity. The movement of ANY process liquids during pumping, emptying, filling and spraying can cause electrostatic accumulation. Movement of other materials, such as powders or a printing web, or cleaning operations, can also create static electricity hazards. Non-conducting footwear and clothing made of...

Read More

December 30, 2011

This regulatory requirement is often mismanaged, which oftentimes results in many other related issues within a process safety management system. In this article, I will discuss a methodology a facility can apply in establishing its “safe upper and lower limits.” In this example, I will use process pressure, as it is the easiest to illustrate, but this same methodology can be applied to establishing...

Read More

December 29, 2011

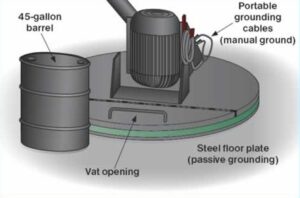

A worker was preparing to mix chemicals in a large in-floor vat in order to make lacquer. After removing the bungs from a steel barrel of toluene, the worker lowered the barrel onto its side and placed it on the lip of the in-floor mixing vat. As the toluene was being poured into the vat, a static discharge was produced that caused the toluene vapour to ignite. This in turn caused the toluene liquid...

Read More

December 29, 2011

MANY THANKS to my NEW & RENEWING “Partners in Safety”for their support! City of Boise, ID since 2007, Haynes since 2005, Air Products since 2009, Benjamin Moore Paints since 2011 2011 Fatality Tracker Electrical 81 (2010 = 90) (2009 = 100) Forklift/Manlift Mobile Equipment 84 (2010 = 110) (2009=88) Mining 248 (2010 = 480) (2009 = 586)...

Read More

December 28, 2011

Key provisions of PSM OSHA’s preamble to the PSM Standard goes a long way to provide us insight as to why there are 14 elements to the standard and what each requirement in each element is intended to serve. The entire preamble is a very long read, but there are some key provisions in Section 3 – III. Summary and Explanation of the Final Rule. I have posted those provisions...

Read More

December 27, 2011

A requirement that many think is “common sense” and “simple” continues to appear on 3rd party audit reports and OSHA/EPA citations year after year. So why is something so “common” and “simple” so difficult to comply with? Often times we make something simple to difficult for our own good. In this article I want to offer some suggestions on how we should...

Read More