CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

We offer:

- Over 17,600 categorized unsafe acts/conditions and accident/injury photos

- Over 1,450 ppt's & doc's

- Over 3,975 technical articles on Process Safety & Occupational Safety & Health matters

- Over 450 videos

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

August 23, 2023

Never forget that management is intended to drive the “safety vehicle.”

We are just the GPS navigation helping plot the course and stay on course.

Read More

August 23, 2023

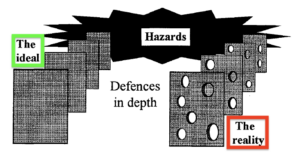

Professor James Reason had a similar image to today’s “Work as imagined vs. Work as done” model. This image is from his 1997 book titled “Managing the Risks of Organizational Accidents“ It shows the “ideal” layers of protection model (i.e., the pieces of cheese with no holes) vs. the “reality” (i.e., the pieces of cheese with many holes) …...

Read More

August 22, 2023

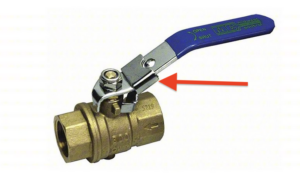

One of the most common valves used in industrial settings is the 1/4-turn ball valve. From 1/4″ up to 6″, these valves are everywhere, regardless of the risks they may pose. Recently a client and I discussed these valves and their risk in highly hazardous chemical processing. I have had several incidents over my career where this type of valve led to LOPC events, some...

Read More

August 21, 2023

The 100-Hour Rule is the theory that to master a topic and get the benefits of greatness doesn’t need to take 10,000 hours. Rather, it can often take approximately 100 hours if you break down skills into rare and valuable micro-skills. It is an exciting study that seems to have some validity to it. Basically, if we spent just 18 minutes a day (100 hours a year), we could master a skill. Now industrial...

Read More

August 21, 2023

What is the difference between “root cause” and “direct cause”? (Please note that I am only using the single tense of these terms in the question; I am not implying these causes can only be singular.) But I tend to see a lot of “direct causes” being tagged as “root causes,” and in my eye, they can be and typically are vastly different. Example: a pleasure craft (boat) sank, killing both parties on...

Read More

August 20, 2023

“A major flaw in our system of government, and even in industry, is the latitude allowed to do less than is necessary. Too often, officials are willing to accept and adapt to situations they know to be wrong. The tendency is to down-play problems instead of actively trying to correct them. Recognizing this, many subordinates give up, contain their views within themselves, and wait for others...

Read More

August 19, 2023

Most of us who were adults in the 2000s can recall some silly claims made by “Infomercials.” You know… “The Juicer,” the “no-stick pan,” the “Snuggie,” the knives that slice a beer can and tomatoes, the “Shamwow” towel, and the list go on and on. Oh man, could they make the product seem as if you just had to have it, that...

Read More

August 19, 2023

Disclaimer: I am not a psychologist but have stayed at a Holiday Inn Express once or twice! This is my take on why “safety affirmations” like “Safety is #1“, “Safety is our top priority,” etc. fail time and again. Most everyone has heard of “affirmations.” These are the daily and deliberate things one says to oneself to change...

Read More

August 18, 2023

Ten (10) core principles shape a “culture of safety.” Each may need a specific plan to develop, improve, or maintain while the others develop.

Safety Culture – The shared values, actions, and behaviors that demonstrate a commitment to safety over competing goals and demands.

…

HomeRead More »

Read More

August 18, 2023

This 5-minute video from our friends “way down under” in New Zealand (NZ) is just three safety pros explaining their roles in implementing and managing risks using the NZ Aviation Safety Management System (SMS). These are three pros talking like real safety pros from the trenches, and they nailed it. Many organizations struggle with the “Role of a Safety Professional”...

Read More

August 18, 2023

In essence, Quality Assurance is about determining gaps in the SMS elements based on non-compliance with regulatory or organizational requirements. It is looking at weaknesses in the safety management system, which increases risk. Like the quality assurance process, the safety assurance process includes requirements for analysis, documentation, auditing, and management review to meet performance...

Read More

August 17, 2023

There is a push by the transportation businesses to allow for single-crew cockpits in planes and trains, like what is allowed in commercial trucking. But is the risk the same across all three modes of transportation? Take the worst-case scenario you can reasonably identify in all three (3) modes and ask… what layers of protection would allow the train or plane to recover safely should...

Read More