SAFTENG Has

- Over 17,500 categorized unsafe acts/conditions and accident/injury photos

- Over 1,400 ppt's & doc's

- Over 3,900 technical articles on Process Safety & Occupational Safety & Health matters

- Over 400 videos

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

I am proud to announce that have extended our”Partners in Safety” agreement for another year (2025).

CI Members, send me an e-mail to request your FREE SAFTENG membership.

October 27, 2020

This safety alert is issued following an incident involving two explosions of ammonia gas cylinders at an ammonia gas filling and bottling plant. The plant has been operating for more than 20 years. The ammonia stock from the suppliers will be stored first in the bulk storage tanks with a capacity of 500 and 900 tons waiting to be transferred or filled into the ammonia gas cylinders. The capacities...

Read More

October 22, 2020

If you’re installing/repairing/modifying your chemical process piping using ASME B31.3 and 31.5, these standards have some strict QA/QA requirements for who can make the welds to join the piping. These welders MUST be qualified in accordance with ASME Code, Section IX, “Welding Qualifications.”

ASME Code, Section IX, Part QW-103.1, states that:

“Each manufacturer or contractor is...

Read More

October 22, 2020

At the Facility, Respondent produces, processes, stores, or handles more than 10,000 pounds of ethylene oxide. On November 3, 2019, the Glycol 2 Production Unit experienced a release of ethylene oxide. Respondent’s Glycol 2 Production Unit experienced an ethylene oxide release involving the knockout pot D-410 of the Ethylene Oxide Scrubber Process. In response to level fluctuations in acid...

Read More

October 22, 2020

We have seen hundreds of changes to our businesses since March and many of these changes were needed for worker protection, but recently we came across one such change that had serious potential to cause a bad event! Maybe you have seen the latest and greatest devices for aiding in our “social distancing” efforts. These devices appear to be marketed towards office and healthcare...

Read More

October 22, 2020

In workplaces that handle/store hazardous materials, there is a need for exhaust ventilation systems when these “Control Areas” exceed the maximum allowable quantities (MAQ) of these hazardous materials. I have used the International Mechanical Code (IMC) as my baseline code for 20+ years. We see this code’s basic requirements in a lot of OSHA standards and other engineering...

Read More

October 19, 2020

Respondent operated a facility to store and distribute pesticides, fertilizers, and industrial chemicals, including chlorine. At all times relevant to this CAFO, the facility produced, used or stored more than 10,000 pounds of chlorine and was subject to the requirements of CAA § 112(r)(7). The process was subject to Program 3 requirements because it was subject to the OSHA process safety management...

Read More

October 19, 2020

An increased number of gas release incidents have occurred in the Gulf of Mexico Region due to leaks from cracked welds, ring gaskets, flange gaskets, inlet nozzles, pipeline risers, suction headers, pressure safety valves (PSVs), and fuel gas lines. These gas release incidents involve deficiencies in Quality Assurance and Mechanical Integrity programs and are caused by corrosion of process piping...

Read More

October 18, 2020

The National Transportation Safety Board determines that the probable cause of the explosion aboard the barge IB1940was the company’s incomplete procedures that did not incorporate the safety instructions included in the Facility Operations Manual regarding the electrical bonding of air movers to barges, resulting in an unbonded air mover being operated in a cargo tank with residual acetone, thereby...

Read More

October 18, 2020

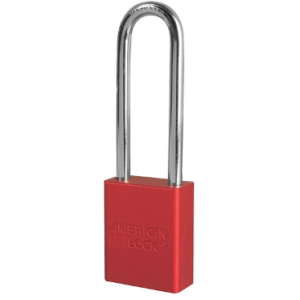

This is a written explanation of how I was taught to perform Group Lockout and how to manage contractors working on-site under a Group Lockout. There are many things in this document that are NOT required by OSHA; however, they are in the program to ensure compliance with OSHA’s minimum expectations. We did it this way after many near misses over my career involving “group LOTO”...

Read More

October 12, 2020

Respondent is the owner and operator of a facility where on October 13, 2019, there was an incident at the Facility that resulted in an accidental release. On April 4, 2020, the EPA requested, and Respondent provided, documentation and information concerning the Incident and Respondent’s compliance with Section 112(r) of the CAA and 40 C.F.R. Part 68. Corroded piping caused a leak of approximately...

Read More

October 11, 2020

It has been 36 years since the Bhopal tragedy killed thousands of people late one night when it was released from its process. I was recently surprised by a facility claiming that the incident was “overblown” and that “MIC is a vital chemical to commerce around the world”. I can’t disagree with the second statement, but I got myself in trouble pushing back...

Read More

October 11, 2020

Both OSHA and the International Fire Code use the Lethal-Dose 50 (LD50) to establish the toxicity of hazardous chemicals/materials and both use the metric milligram per kilogram of body weight in their assessments. Just so we all have an idea of how small a milligram is…

One (1) grain of sand weighs 1 mg

An average-sized ant will weigh around 2 mg

So we are talking about some REALLY toxic...

Read More