CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact me

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

November 16, 2024

Please keep in mind that I am speaking strictly in terms of “complying” with required baseline standards and codes. Is 10,000% compliance a pipe dream? Should it be an expectation of the business leaders? 10,000% means 100% compliance -100% of the time. Remember, these are baseline standards/codes that have been in place for 40-50+ years and many businesses have been in business this long or longer....

Read More

November 16, 2024

This Louisville explosion has started the debate about the plant being in a residential area. What most of the media and local politicians fail to mention is that the plant has been there since 1948. The neighborhood was allowed to build up around it because of lax zoning and spineless politicians. So to blame the business for being there first is a bit rich for me to swallow. https://apnews.com/a...

Read More

November 16, 2024

For example, the popularity of flammable refrigerants. The risk is real! R-600a is an isobutane, a flammable substance like you might find in a cigarette lighter. https://www.wftv.com/news/local/it-blew-right-across-his-home-appliance-expert-warns-about-potentially-explosive-refrigerators/T7MZ3NZXQZBVRIXEKEFYIASOQQ/?fbclid=IwY2xjawGk79ZleHRuA2FlbQIxMQABHUSSh_owUKgWKjC4TZImcC-Gmc9RGcLqgzWxhlB6Iq8tN...

Read More

November 16, 2024

A couple of KEY items, reading between the lines: Discharge from the PRV was HORIZONTAL through a horizontal tee, not UPWARDS, and UNOBSTRUCTED. The release was OUTSIDE, yet the facility evacuated, and some workers evacuated into the NH3 cloud that had formed (see image below) Only 170 pounds of NH3 was released. Forty people working at the Cuisine Solutions facility were evaluated at various local...

Read More

November 14, 2024

The Courier-Journal has released more photos. Below is my analysis of these photos, using their and Google Maps road images. The first image below is the PRE-EXPLOSION image. In it, we can see the two (2) standing cooling towers/condensers. The one in the blue box is the one that was destroyed and came to rest in front of the larger tower. The red box is the suspected location; I think the vessel was...

Read More

November 14, 2024

A few years ago, I put forth the idea that workers pass through the 3 Cs in their decision-making process as they learn to take more and more risks. Those three (3) Cs were: Concerned (as they begin their job) Comfortable (as they get positive consequences from their at-risk behavior) Confident (they think they can do the job breaking the rules and nothing bad is going to happen) That article...

Read More

November 14, 2024

For each one of my Advanced SMS courses, I always start the course by having the students list the 16 Elements of the SAFTENG Safety Process/SMS in order of importance. I tell them there is no right or wrong answer. Over the past couple of years, I began to keep the answers to the questions as there is a distinct difference between how we, as safety pros, see the elements and how operations,...

Read More

November 13, 2024

This week, we saw a fatal explosion in Louisville, KY. This same facility, albeit under a previous ownership, had a catastrophic failure of a PV in 2003. The photos coming out of the post-analysis of this week’s event look to be a similar type of explosion. CLICK HERE to see the pics. Here is my analysis, using the pics to piece the event. I am NOT involved in this investigation, but I have participated...

Read More

November 11, 2024

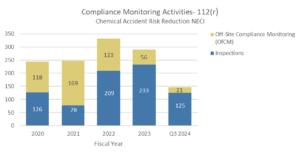

Inspections As of the 3rd quarter of the fiscal year (Q3), EPA completed 133 CAA Section 112(r) (Risk Management Program) inspections. Enforcement Cases As of the 3rd quarter of the fiscal year (Q3), EPA took action at 73 facilities to decrease the likelihood of chemical accidents. Sasol Chemicals: In April 2024, EPA finalized a settlement with Sasol Chemicals (Sasol) over alleged violations...

Read More

November 9, 2024

This is one of the most requested presentations I use when working with C-Suite Executives and Senior Safety Leadership.

Safety Leadership and CultureDownload

Read More

November 9, 2024

This is a presentation I use when doing some of my SMS and Incident Management training courses.

Incident Management (SMS)Download

Read More

November 6, 2024

I teach about a dozen flammable liquid courses annually, and it is one of my favorite courses to teach, as I love the technical side of hazardous materials. And my course always starts with a discussion around the 1st step in making a flammable liquid a hazardous material… FLASH POINT. And over the 30+ years, I have been teaching people about flammable liquids when I ask the class to explain...

Read More