Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

September 1, 2008

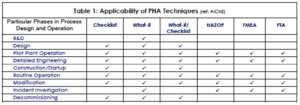

A Process Hazard(s) Analysis is a thorough, orderly, and systematic approach for identifying, evaluating, and controlling the hazards of processes involving highly hazardous chemicals. The facility shall perform a process hazard analysis on all processes covered by EPA’s RMP rule and/or OSHA’s PSM standard. The process hazard analysis methodology selected must be appropriate to the complexity...

Read More

July 17, 2008

HAZWOPER EMERGENCY RESPONSE PLAN DEVELOPMENT GUIDELINES(Elements of an Emergency Response Plan)1910.120(q)(2) (i) Pre-emergency Planning and Coordination with outside parties Facilities are required in the Superfund Amendments and Reauthorization Act (SARA) title III to coordinate their activities with outside response organizations and emergency response organizations. The emergency response...

Read More

June 17, 2008

Are there any recordkeeping requirements specified in the risk management program (RMP) regulations in 40 CFR Part 68?

The owner or operator of a stationary source that is subject to the RMP regulations must maintain records supporting the implementation of Part 68 for five years (§68.200).

Read More

May 21, 2008

Error Management (EM) has two (2) components: error reduction and error containment Error reduction comprises measures designed to limit the occurrence of errors. Since this will never be wholly successful, we also need error containment measures designed to limit the adverse consequences of those errors that still occur. At this general level, EM is indistinguishable from quality management or, indeed,...

Read More

April 12, 2008

Fostering the principles for a strong safety culture is one of the most challenging tasks facing a management team. Successful leadership achieving a strong safety culture will most likely move an organization to the next level of human performance. A leader is any individual who takes personal responsibility for his or her performance as well as the facility’s performance and attempts to influence...

Read More

March 10, 2008

I have used this tool, with some modern-day modifications, for years. When I was a safety manager of a facility I would constantly be looking for these indicators as a means to validate what I was “feeling”. As safety pros, we have a sixth sense of how things are going, but there are so many markers/indicators in measuring safety cultures that having a list like this comes in...

Read More

February 3, 2008

“Name, blame, shame, retrain” is an often-used phrase for older ineffective paradigms of safety management and accident analysis. Dr. Rosabeth Moss Kanter of Harvard Business School phased the situation this way: “Accountability is a favorite word to invoke when the lack of it has become so apparent.” Kanter, 2009 The concepts of accountability, culpability and just culture are inextricably entwined....

Read More

January 26, 2008

Earlier, I outlined the six (6) stages of a Behavior Modification Intervention. Now, I want to discuss how the same six-step process used to change the behaviors of hourly workers can be used to promote critical health and safety behaviors amongst management personnel. Management behavior will heavily influence the success or failure of a Behavior-Based Observation Process, and safety leadership...

Read More

January 26, 2008

Several studies have evaluated the effectiveness of behavioral modification programs in improving workplace safety. These studies have focused on establishing the following: their ability to decrease accidents/injuries, their ability to increase safe behavior and which components in a behavioral observation safety processes are most important in changing unsafe behavior and reducing accidents and injuries...

Read More

January 4, 2008

In many processes, the use of a rupture disc (RD) between the vessel being protected and the Relief Valve (RV) is a fairly common practice. This is ALWAYS done for design necessities and not just “because”. Some processes could be corrosive to the RV internals, at least this is the most common reason for this type of arrangement. There are some process safety professionals...

Read More

December 26, 2007

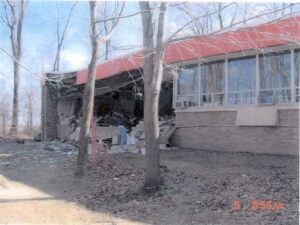

The boiler was in the basement at the rear of the school.

This happen on a Sunday when the school was closed.

If this was during the week there would have been 15 children and a teacher and teacher assistant in that classroom.

The damage was so bad the rear of the school building had to be demolished.

Read More