Let us help you make sense of PSM / RMP!

My friend Brian Chapin will be offering an open-enrollment PSM/RMP class in Burleson, Texas, July 8th to 11th, 2025. Brian is an absolute pro in NH3 Refrigeration Process Safety. Anyone who attends will also get a FREE membership to SAFTENG. You can get more information on the class with this link.

CLICK HERE to Renew your Membership

CLICK HERE for a NEW Membership

CLICK HERE to see eligibility requirements for FREE Membership

If you have any questions, please contact m

SAFTENG has:

- Over 18,000 categorized unsafe acts/conditions and accident/injury photos

- Over 1,500 ppt's & doc's in the SAFTENG Library

- Over 4,000 Technical Articles on Process Safety, Emergency Response & OSH topics

- Over 450 videos (those not allowed on YouTube Channel)

Many THANKS to my NEW Members and those who CONTINUE to support SAFTENG:

April 6, 2025

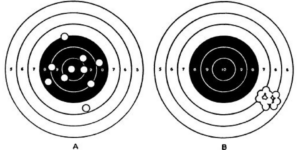

Although it may be possible to accept that errors are neither as numerous nor as varied as they might first appear, the idea of a predictable error is a much harder one to swallow. If errors were indeed predictable, we would surely take steps to avoid them. Yet, they still occur. So, what is a predictable error? Consider the two targets shown in Figure 1.1 (taken from Chapanis, 1951). Each shows a...

Read More

April 5, 2025

When you think you’ve seen it all, someone comes along and proves you WRONG!

…

HomeRead More »

Read More

April 5, 2025

We have discussed these safety-critical valves extensively here at SAFTENG. I am a huge proponent of these valves, and they are required by most State Fire Codes and RAGAGEPs. Yet, we still find far too many processes handling Highly Hazardous Chemicals/Extremely Hazardous Chemicals that are missing this critical safety feature. As we have also discussed, the UNLOADING of the HHC/EHS is by far the...

Read More

April 5, 2025

Most of us have seen a gate valve installed in piping, and 99% of the time, we want to see the valve handle in the VERTICAL-UPWARD position. However, when we need to install an “intervening valve” in the relief path, which ASME allows, we may/should see the valve handle(s) in the Horizontal or below Horizontal position. Here is why… ASME Section XIII, which regulates “interning...

Read More

April 4, 2025

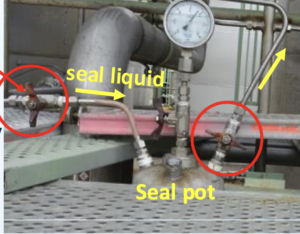

In my time in petro chem I had two releases (Cl2 and Br) that were caused when the handle of a 1/4-turn ball valve (bleed) was accidentally OPENED (one by a utility hose and one by a pant’s leg). Here is another example from The European Process Safety Centre (EPSC) What Happened:During scaffolding maintenance work, a valve was inadvertently opened. This valve was in the refill line of a pump...

Read More

April 4, 2025

ASME has allowed dual PRD systems ever since I started in process safety back in 1993. These systems usually have a Rupture Disc (RD) BEFORE the Pressure Safety Valve (PSV). This is usually done to protect the more expensive and more complicated PSV from the corrosive process gases. Although I never managed a PR system where a RD was placed after the PSV, this too is allowed by the code. This Releif...

Read More

April 3, 2025

For decades, we used Appendix M-5 in Section VIII as our design basis for having intervening/stop valves before and/or after a Pressure Relief Device (PRD). But in 2021 (amid the global pandemic), ASME published its new Section XIII, Rules for Overpressure Protection. We now use Appendix B of this new ASME section when we have a design basis using “stop valves” (or sometimes called...

Read More

April 2, 2025

I was always taught the “bubble test” method had a climate limitation regarding cold ambient temperatures. As we have discussed, ASME B31.3 refers us to ASME Section V for the Bubble Test method for leak testing. It is there we can find the “surface temperature” limitations…

(emphasis is by me)

…

HomeRead More »

Read More

April 1, 2025

Sad state of affairs… At 2:15 p.m. on December 7, 2023, an employee working as a pipefitter for a shipyard was tasked to inspect JP5 tanks to ensure they were safe for a permit required confined space entry and then assist with troubleshooting a repair connection. The employee entered a tank and was overcome by lack of oxygen cause by argon gas. The employee died due to asphyxiation. Norfolk...

Read More

April 1, 2025

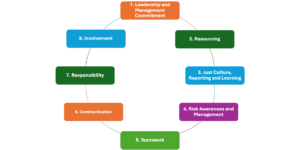

I have uploaded one of my more popular “culture” presentations/exercises I do with senior leaders and their safety leaders. It is a 2-day “reflective” workshop that intends to identify opportunities to improve the culture around safety at an organization. Experienced safety leaders can facilitate this exercise in-house and gain a lot of traction in putting plans in place that...

Read More

April 1, 2025

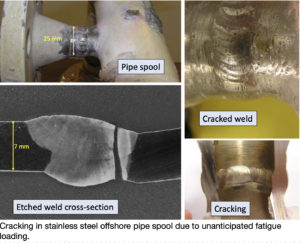

HSE has identified inconsistencies in the application and supervision of welding of safety-critical metallic components, leading to failures with high consequences. Examples include loss of containment of dangerous substances, major structural collapses, and fatalities. HSE specialists carried out a study to identify common causes of these and to highlight priority areas for improvement of weld quality...

Read More

April 1, 2025

I talk a lot about inspecting welds/flanges and then pressure testing and leak testing our piping. However, there is more to this story. Inspecting our piping actually begins before it is installed.

341.4.1 Examination – Normal Fluid Service

…

HomeRead More »

Read More